Measurement Circuit for 3-phase AC Power

The basic principles for measuring the 3-phase AC electrical power were discussed in the article Measurement of 3-phase electrical power which is an theory approach in general. There were discussed several measurement methods, the basic formulas for calculating the AC power and all three power components, the real, the barren and the apparent power. Now, we will take a look at one real measurement circuit for AC power, which is used in practice. The measurement circuit is shown on the Picture 1. In general, this circuit is 3-phase 4-wire with 3 CTs and 2 PTs connection. The same wiring diagram, only without the null wire, is actually the 3-phase 3-wire delta connection 3CT 2PT. Usually, in the high voltage systems, the power line is 3-wire without null connection, only the 3 phases, so, in this case is used 3-phase 3-wire connection. Since our goal here is to explain only the measurement of the AC power, on the circuit are not shown the rest of the components, like high voltage fuses, 3-phase voltage disconnect switch, and so on.

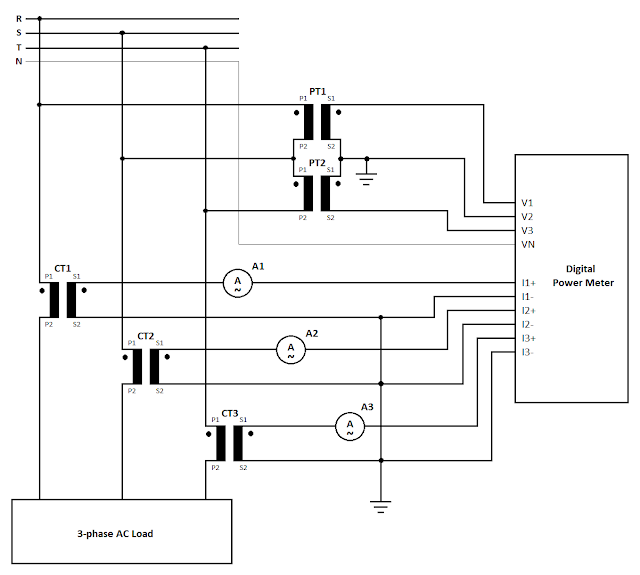

Picture 1: Measurement Circuit for 3-phase AC Power (3CT 2PT Connection)

The 3-phase AC load is connected on the 3-phase power line, phases R, S and T (or, L1, L2 and L3). This load can have different nature, for example, it can be a 3-phase power transformer which runs industrial arc furnace, or whole industrial plant, etc. This circuit actually will measure the AC power which is consumed by the AC load. The measurement circuit here consists 5 measurement transformers, 3 ampere meters and one power meter. The voltage measurement transformers are marked as PT1 and PT2 (PT - Potential transformer). The three current measurement transformers are marked as CT1, CT2 and CT3 (CT - Current transformer). The black dot on the PT symbol is polarity mark of the primary and secondary coils. The connection ends of the primary coils are marked as P1 and P2, where P1 is the start of the coil and P2 is its end, so the polarity mark is at P1. The connection ends of the secondary coils are marked as S1 and S2, where S1 is the start of the coil and S2 is its end, so the polarity mark is at S1. In this kind of circuit connections the very important thing is to keep the proper polarity in order to achieve the correct measuring results, otherwise, if the any of the circuit elements is connected with wrong polarity, the measurement results will be wrong at big scale.

First, let's take a look at the PTs connection. Here, we have 3 phases and only 2 PTs, and they are connected in the so called "V" connection. As it's shown on the circuit, the first phase R (L1) is connected to the P1 connector of the PT1. The second phase S (L2) is connected to the P2 connector of the PT1 and the P1 connector of the PT2, which are both connected together. Finally, the third phase T (L3) is connected to the P2 connector of the PT2. The secondary connector S2 of the PT1 and S1 of the PT2 are also both connected together and to earth ground. We can mention here, that if we swap the P1 and P2 of primary, and the S1 and S2 of secondary connections of the PT2 nothing will change, since these two connections in the 2PT system are equivalent. This actually comes from one simple rule for transformers, namely, if you change the polarity of the primary coil connection, always change and the polarity of the secondary coil connection. The current transformers are connected at each phase in the direction of the energy flow. In other words, the AC load consumes power, so the energy flows through it in the direction from the power line to the AC load. Therefore, the phase R enters the CT1 in its P1 connector and exits from its P2 connector, the phase S enters the CT2 in P1 and exits from P2, and finally, the phase T enters the CT3 in P1 and exits from P2. The very important thing for current transformers is that the secondary circuits must be closed! If the secondary coil of the CT is open, that can damage the transformer and all elements connected to the secondary circuit as a result of a high voltage. Here, the secondary circuit of the CT1 is closed starting from S1 through the analog ampere meter A1, entering the first phase current input into the digital power meter in I1+ connector, exiting from I1- connector and closing this circuit in S2 connector of CT1. The CT2 secondary circuit starts from its S1 connector, through the A2, entering the I2+, exiting at I2-, and ends in the S2. And finally, the CT3 secondary circuit starts from its S1 connector, through the A3, entering the I3+, exiting at I3-, and ends at S2. The analog ampere meters A1, A2 and A3 are usually mounted on the monitoring pult for visual presentation of the current consumption per phase of the AC load. Anyway, these currents can be read from the digital power meter. The voltage inputs of the power meter V1, V2, V3 and VN are connected as is shown on the Picture 1.

In order to display the correct values of all measured currents, voltages, powers and so on, the digital power meter should be parameterized according to the measurement equipment used in the circuit. That means that the transformation ratios of all measurement transformers must be entered as parameters into the digital power meter. After proper data is entered, the power meter will measure the AC power that the load consumes from the power line. The new digital power meters have a lot of options for setting, and they measure not only the power, but all other system variables, as currents per phase, line and phase voltages, the real, the barren and the apparent power and energy that was consumed during the specified time interval. Also, power meter measures the power factor of the system, the frequency of the voltage, the THD factor (total harmonic distortion) of the current and line and phase voltages, it registers the peak values and the minimum values, has a timer function and a port for data transfer, like RS232 or RS485, depending on the model.

The wiring diagram shown on Picture 1 is most use in practical high voltage applications. Here, the voltage is measured using 2 PTs, and in case when 3 PTs are used, they are all connected with one phase and ground. From the other hand, if the system works on low voltage lines, for example, 220 V AC, then the power meter can be connected directly to each phase and null without using the voltage measurement transformers. However, in the practice, the wiring configuration can vary a lot, depending on the used measurement equipment. There can be systems with 1 phase 1 CT and no PT, 3 phase 2 CT no PT, 3 phase 3 CT no PT, 3-phase 3 CT 2 PT, 3-phase 3 CT 3 PT, and so on. Depending on the used wiring diagram, the power meter should be configured correctly, setting up the system type in order to display the real values of the variables measured in the system.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment