A transformer has no internal moving parts, and it transfers energy from one circuit to another by electromagnetic induction. External cooling may include heat exchangers, radiators, fans, and oil pumps. Radiators and fans are evident in Picture 1. The large horizontal tank at the top is a conservator. Transformers are typically used because a change in voltage is needed. Power transformers are defined as transformers rated 500 kVA and larger. Larger transformers are oil-filled for insulation and cooling. A typical Generator step-up (GSU) transformer may contain several thousand gallons of oil. One must always be aware of the possibility of spills, leaks, fires, and environmental risks this oil poses.

Picture 1: Typical GSU Three-Phase Transformer

Transformers smaller than 500 kVA are generally called distribution transformers. Pole-top and small, pad-mounted transformers that serve residences and small businesses are typically distribution transformers. Generator step-up transformers, used in powerplants, receive electrical energy at generator voltage and increase it to a higher voltage for transmission lines. Conversely, a step-down transformer receives energy at a higher voltage and delivers it at a lower voltage for distribution to various loads. All electrical devices using coils (in this case, transformers) are constant wattage devices. This means voltage multiplied by current must remain constant; therefore, when voltage is “stepped-up,” the current is “stepped-down” (and vice versa). Transformers transfer electrical energy between circuits completely insulated from each other. This makes it possible to use very high (stepped-up) voltages for transmission lines, resulting in a lower (stepped-down) current.

Higher voltage and lower current reduce the required size and cost of transmission lines and reduce transmission losses as well. Transformers have made possible economic delivery of electric power over long distances. Transformers do not require as much attention as most other equipment. However, the care and maintenance they do require is absolutely critical. Because of their reliability, maintenance is sometimes ignored, causing reduced service life and, at times, outright failure.

Principle of Operation

Transformer function is based on the principle that electrical energy is transferred efficiently by magnetic induction from one circuit to another. When one winding of a transformer is energized from an alternating current (AC) source, an alternating magnetic field is established in the transformer core. Alternating magnetic lines of force, called “flux,” circulate through the core. With a second winding around the same core, a voltage is induced by the alternating flux lines. A circuit, connected to the terminals of the second winding, results in current flow. Each phase of a transformer is composed of two separate coil windings wound on a common core. The low-voltage winding is placed nearest the core; the high-voltage winding is then placed around both the low voltage winding and core. See Picture 2 which shows internal construction of one phase. The core is typically made from very thin steel laminations, each coated with insulation. By insulating between individual laminations, losses are reduced. The steel core provides a low resistance path for magnetic flux. Both high and low voltage windings are insulated from the core and from each other, and leads are brought out through insulating bushings. A three-phase transformer typically has a core with three legs and has both high voltage and low voltage windings around each leg. Special paper and wood are used for insulation and internal structural support.

Picture 2: Transformer Construction

Transformer Action

Transformer action depends upon magnetic lines of force (flux) mentioned above. At the instant a transformer primary is energized with AC, a flow of electrons (current) begins. During the instant of switch closing, buildup of current and magnetic field occurs. As current begins the positive portion of the sine wave, lines of magnetic force (flux) develop outward from the coil and continue to expand until the current is at its positive peak. The magnetic field is also at its positive peak. The current sine wave then begins to decrease, crosses zero, and goes negative until it reaches its negative peak. The magnetic flux switches direction and also reaches its peak in the opposite direction. With an AC power circuit, the current changes (alternates) continually 60 times per second, which is standard in the United States. Other countries may use other frequencies. In Europe, 50 cycles per second is common. Strength of a magnetic field depends on the amount of current and number of turns in the winding. When current is reduced, the magnetic field shrinks. When the current is switched off, the magnetic field collapses.

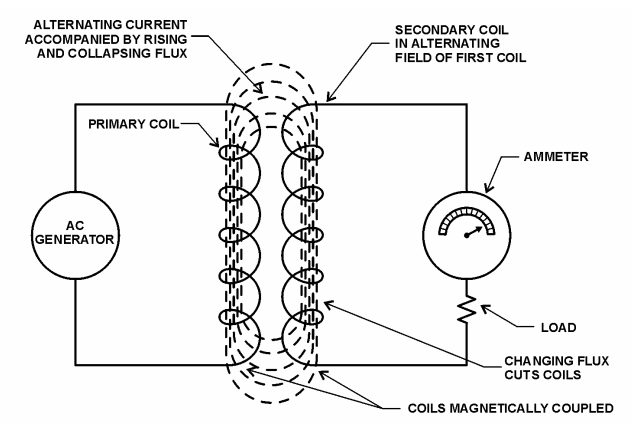

When a coil is placed in an AC circuit, as shown in Picture 3, current in the primary coil will be accompanied by a constantly rising and collapsing magnetic field. When another coil is placed within the alternating magnetic field of the first coil, the rising and collapsing flux will induce voltage in the second coil. When an external circuit is connected to the second coil, the induced voltage in the coil will cause a current in the second coil. The coils are said to be magnetically coupled; they are, however, electrically isolated from each other.

Many transformers have separate coils, as shown in Picture 3, and contain many turns of wire and a magnetic core, which forms a path for and concentrates the magnetic flux. The winding receiving electrical energy from the source is called the primary winding. The winding which receives energy from the primary winding, via the magnetic field, is called the “secondary” winding. Either the high or low voltage winding can be the primary or the secondary. With GSUs at powerplants, the primary winding is the low-voltage side (generator voltage), and the highvoltage side is the secondary winding (transmission voltage). Where power is used (i.e., at residences or businesses), the primary winding is the high-voltage side, and the secondary winding is the low-voltage side.

Picture 3: Transformer Action

The amount of voltage induced in each turn of the secondary winding will be the same as the voltage across each turn of the primary winding. The total amount of voltage induced will be equal to the sum of the voltages induced in each turn. Therefore, if the secondary winding has more turns than the primary, a greater voltage will be induced in the secondary, and the transformer is known as a step-up transformer. If the secondary winding has fewer turns than the primary, a lower voltage will be induced in the secondary, and the transformer is a step-down transformer. Note that the primary is always connected to the source of power, and the secondary is always connected to the load. In actual practice, the amount of power available from the secondary will be slightly less than the amount supplied to the primary because of losses in the transformer itself.

Picture 4: Transformer

The voltage induced in the primary circuit opposes the applied voltage and is known as back voltage or back electro-motive-force (back EMF). When the secondary circuit is open, back EMF, along with the primary circuit resistance, acts to limit the primary current. Primary current must be sufficient to maintain enough magnetic field to produce the required back EMF. When the secondary circuit is closed and a load is applied, current appears in the secondary due to induced voltage, resulting from flux created by the primary current. This secondary current sets up a second magnetic field in the transformer in the opposite direction of the primary field. Thus, the two fields oppose each other and result in a combined magnetic field of less strength than the single field produced by the primary with the secondary open. This reduces the back voltage (back EMF) of the primary and causes the primary current to increase. The primary current increases until it reestablishes the total magnetic field at its original strength.

In transformers, a balanced condition must always exist between the primary and secondary magnetic fields. Volts times amperes (amps) must also be balanced (be the same) on both primary and secondary. The required primary voltage and current must be supplied to maintain the transformer losses and secondary load.

No comments:

Post a Comment