Testing of Closed Control Loops, Binary Control Systems and Safety Devices

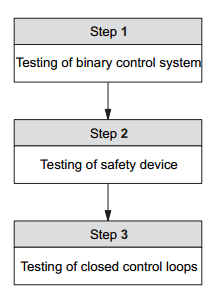

When the required auxiliary energies have been made available, the testing of the automation configuration/structure can be started. The following procedure is recommended to successfully realise this task (Picture 1).

Picture 1: Testing of automation configuration of a technical process system

With step 1, the binary control systems are tested as a first measure. This involves, for example, the testing of the on/off valves provided for configurational changes and their interaction with the corresponding binary controllers. In this connection, the signals resulting from the so-called final control element feedback in particular are to be evaluated visually or by means of binary monitoring (binary control systems). Similarly, the allocated binary control systems for the switching on and off of corresponding pumps and heaters are to be tested. Here again, the allocated binary control systems are to be tested via the manual control elements and corresponding feedback sensors.

Equally, the testing of safety devices also includes the monitoring of binary control systems. However, to do this, the associated sensors are to be activated by means of suitable manipulation and any actuators thus actuated evaluated in the familiar manner for correct functioning (visual and logic final control element acknowledgement). If the binary control systems including safety devices are then fully functional, the actual commissioning of the closed control loop can be started. To do this, the closed control loops are brought into line with the respective specified working points in manual mode and then switched over to automatic mode. After a sufficiently long evaluation of the guiding and interference behaviour of the activated closed control loops, the system can be handed over to the user.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment