Single-Phase Transformer Connections for Typical Service to Buildings

Picture 1 shows a typical arrangement of bringing leads out of a single-phase distribution transformer. To provide flexibility for connection, the secondary winding is arranged in two sections. Each section has the same number of turns and, consequently, the same voltage. Two primary leads (H1, H2) are brought out from the top through porcelain bushings. Three secondary leads (X1, X2, X3) are brought out through insulating bushings on the side of the tank, one lead from the center tap (neutral) (X2) and one from each end of the secondary coil (X1 and X3). Connections, as shown, are typical of services to homes and small businesses. This connection provides a three-wire service that permits adequate capacity at minimum cost. The neutral wire (X2) (center tap) is grounded. A 120-volt circuit is between the neutral and each of the other leads, and a 240-volt circuit is between the two ungrounded leads.

Picture 1: Single-Phase Transformer

Parallel Operation of Single-Phase Transformers for Additional Capacity

In perfect parallel operation of two or more transformers, current in each transformer would be directly proportional to the transformer capacity, and the arithmetic sum would equal one-half the total current. In practice, this is seldom achieved because of small variations in transformers. However, there are conditions for operating transformers in parallel. They are:

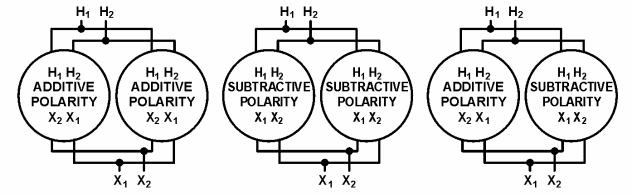

- Any combination of positive and negative polarity transformers can be used. However, in all cases, numerical notations must be followed on both primary and secondary connections. That is H1 connected to H1, H2 connected to H2, and X1 connected to X1, X2 connected to X2, X3 connected to X3. Note that each subscript number on a transformer must be connected to the same subscript number on the other transformer as shown in Picture 2.

- Tap settings must be identical.

- Voltage ratings must be identical; this, of course, makes the turns ratios also identical.

- The percent impedance of one transformer must be between 92½% and 107½% of the other. Otherwise, circulating currents between the two transformers would be excessive.

- Frequencies must be identical. Standard frequency in the United States is 60 hertz and usually will not present a problem.

Picture 2: Single-Phase Paralleling

CAUTION: With positive and negative polarity transformers, the location of X1 and X2 connections on the tanks will be reversed. Care must be exercised to ensure that terminals are connected, as stated above. See Picture 2.

One will notice, from the above requirements, that paralleled transformers do not have to be the same size. However, to meet the percent impedance requirement, they must be nearly the same size. Most utilities will not parallel transformers if they are more than one standard kVA size rating different from each other, otherwise, circulating currents are excessive.

No comments:

Post a Comment