A motor’s enclosure not only holds the motors components together, it also protects the internal components from moisture and containments. The degree of protection depends on the enclosure type. In addition, the type of enclosure affects the motor’s cooling. There are two categories of enclosures: open and totally enclosed.

Open Drip Proof (ODP) Enclosure

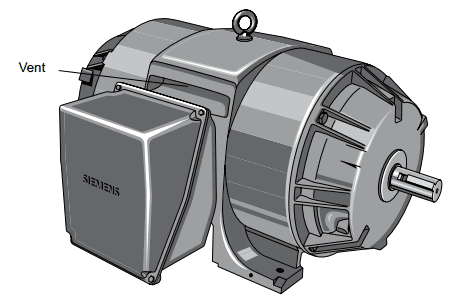

Open enclosures permit cooling air to flow through the motor. One type of open enclosure is the open drip proof (ODP) enclosure (Picture 1). This enclosure has vents that allow for air flow. Fan blades attached to the rotor move air through the motor when the rotor is turning. The vents are positioned so that liquids and solids falling from above at angles up to 15° from vertical cannot enter the interior of the motor when the motor is mounted on a horizontal surface. When the motor is mounted on a vertical surface, such as a wall or panel, a special cover may be needed. ODP enclosures should be used in environments free from contaminates.

Picture 1: ODP Enclosure

Totally Enclosed Non-Ventilated (TENV) Enclosure

In some applications, the air surrounding the motor contains corrosive or harmful elements which can damage the internal parts of a motor. A totally enclosed non-ventilated (TENV) motor enclosure limits the flow of air into the motor, but is not airtight (Picture 2). However, a seal at the point where the shaft passes through the housing prevents water, dust, and other foreign matter from entering the motor along the shaft. Most TENV motors are fractional horsepower. However, integral horsepower TENV motors are used for special applications. The absence of ventilating openings means that all the heat from inside the motor must dissipate through the enclosure by conduction. These larger horsepower TENV motors have an enclosure that is heavily ribbed to help dissipate heat more quickly. TENV motors can be used indoors or outdoors.

Picture 2: TENV Enclosure

Totally Enclosed Fan Cooled (TEFC) Enclosure

A totally enclosed fan-cooled (TEFC) motor is similar to a TENV motor, but has an external fan mounted opposite the drive end of the motor (Picture 3). The fan blows air over the motor’s exterior for additional cooling. The fan is covered by a shroud to prevent anyone from touching it. TEFC motors can be used in dirty, moist, or mildly corrosive environments.

Picture 3: TEFC Enclosure

Explosion Proof (XP)

Hazardous duty applications are commonly found in chemical processing, mining, foundry, pulp and paper, waste management, and petrochemical industries. In these applications, motors have to comply with the strictest safety standards for the protection of life, machines and the environment. This often requires use of explosion proof (XP) motors. An XP motor is similar in appearance to a TEFC motor, however, most XP enclosures are cast iron (Picture 4). In the United States, the application of motors in hazardous locations is subject to National Electrical Code® and standards set by Underwriters Laboratories and various regulatory agencies.

Picture 4: XP Enclosure

Hazardous (Classified) Locations

You should never specify or suggest the type of hazardous location classification, it is the user’s responsibility to comply with all applicable codes and to contact local regulatory agencies to define hazardous locations. Refer to the National Electrical Code®Article 500 for additional information.

Division I and II Locations

Division I locations normally have hazardous materials present in the atmosphere. Division II locations may have hazardous material present in the atmosphere under abnormal conditions.

Classes and Groups

Locations defined as hazardous, are further defined by the class and group of hazard. For example, Class I, Groups A through D have gases or vapors present. Class II, Groups E, F, and G have flammable dust, such as coke or grain dust. Class III is not divided into groups. This class involves ignitable fibers and lints (Picture 5).

Picture 5: Classes and Groups table

No comments:

Post a Comment