As already described, the project design work also includes the appropriate project documentation for the provision of the electrical, pneumatic and hydraulic auxiliary energy, apart from the core project. Due to the technical specifics and considerable amount of work involved, the electrical project accounts for the greater part except for the core project. The principal outlines of the electrical project design are therefore introduced in shortened form.

Determining the required electrical power (connected load)

The first point to be established is what electrical connected load is to be made available for the operation of the automation system. This is assessed on the basis of the preliminary EMCS block diagram and the automation equipment set out in the equipment list and the required electrical voltages (e.g. 230 V AC, 24 V DC) and capacities established. All EMCS points are subject to these analyses and the entire electrical power required determined by way of coordinating these.

Regarding the connection/combination of electrical project and core project

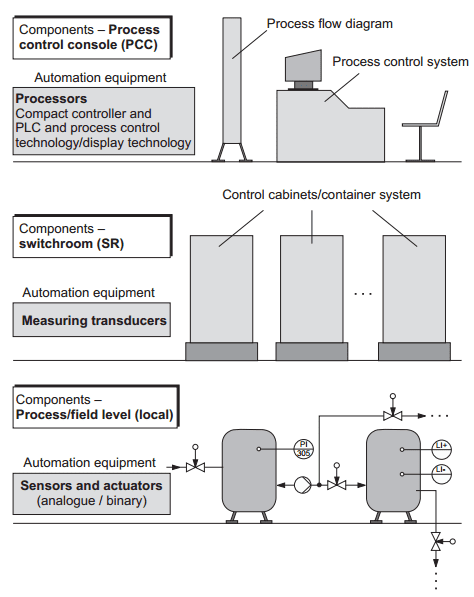

The EMCS block diagram based on the preliminary EMCS block diagram also defines the detailed cabling for the required voltage supplies. This highlights the relevance of the question for an interface for the respective reduction of the required voltages. Picture 1 illustrates a structure, which provides a solution to this problem.

Picture 1: Combination of core project with electrical and pneumatic project

This means that the selection of a voltage-proof terminal distributor provides a means of connecting the voltages resulting from the electrical project established on the input side and conducting these to the EMCS points on the output side of the terminal distributor. This allocation (block diagram) is uniquely documented in the so-called connection list. As Picture 1 also shows, this principle is also used to realise the supply of pneumatic and hydraulic auxiliary energy (connection list). Moreover, reference is also made to the additional problems to be solved of EMC and lightning and explosion protection.

Distribution of auxiliary electrical power

Based on the established connected load, a favourable structure is to be developed for the distribution of this electrical power. In accordance with the PI flow diagram familiar from the core project design, a general structure is also required for the distribution of the electrical auxiliary power with regard to the electrical project. Picture 2 shows a generally applicable and typical structure for this. When the electrical project is further configured, this needs to be expanded by a second version comprising documentation of basic wiring and switching devices.

Picture 2: Basic structure for distribution of electrical auxiliary energy

Depending on the extent of the electrical project, this general overview is followed by a further breakdown into one or several levels, by developing the so-called circuit diagrams, which are also based on the EMCS block diagrams realised during the core project design. These circuit diagrams define the detailed distribution (wiring) of the electrical auxiliary power. The example of a typical component is used – connection of the auxiliary electrical power – to define the circuit diagram (Picture 3) for the latching connection of processors and three-phase current consuming devices. This circuit diagram illustrates for instance that the processors and current consuming devices must always be connected separately or that for reasons of safety, two contactors (C1/C2; C3/C4) must always be released when these are switched off or in the case of an emergency-stop.

Picture 3: Circuit diagrams for electrical auxiliary energy (self-latching) for processors/PLC technology and three-phase consuming devices

Understandably, the above information merely provides an idea of the extent and technical contents of electrical project design. In the sense of a holistic preparation of the project of an automation system, it is essential to remember that, apart from the core project design, the electrical project design is the fundamental basis. This fact should be taken into account with regard to the time schedule and cost plan to ensure the success of the project design work.

Notes regarding assembly project design

Apart from the core and electrical project design, the assembly project design represents the most important aspect for the realisation of an automation system. It takes into account all the construction and assembly technological aspects. Based on the design of the process technology system, including any associated building components, the assembly project design deals with problems such as:

>> configuration of the cable run guides (for EMCS and electrotechnology);

>> determining of material requirements for cable runs (number of cable run components, supports, brackets, etc.);

>> determining of cable lengths and types of cable, design and construction of cable harnesses;

>> spatial planning of the required container units and auxiliary units (e. g. compressor room, emergency power source) etc.

These services must also be implemented with the greatest of care, since they are crucial in determining the cost efficiency and schedule effectiveness of the practical realisation (assembly) of an automation system.