One way to evaluate whether the torque capabilities of a motor meet the torque requirements of the load is to compare the motor’s speed-torque curve with the speed-torque requirements of the load (Picture 1).

Picture 1: Speed-torque curve of the motor and speed-torque requirements of the load

Load Characteristics Tables

A table, like one shown on Picture 2 below, can be used to find the load torque characteristics. NEMA publication MG 1 is one source of typical torque characteristics.

Picture 2: Load torque characteristics table (example)

Calculating Load Torque

The most accurate way to obtain torque characteristics of a given load is from the equipment manufacturer. However, the following procedure illustrates how load torque can be determined. The following illustration on Picture 3 shows a pulley fastened to the shaft of a load. A cord is wrapped around the pulley with one end connected to a spring scale. Pull on the scale until the shaft turns and note the force reading on the scale. Then, multiply the force required to turn the shaft by the radius of the pulley to calculate the torque value. Keep in mind that the radius is measured from the center of the shaft.

Picture 3: Load torque measurement

For example, if the radius of the pulley is 1 foot and the force required to turn the shaft is 10 pounds, the torque requirement is 10 lb-ft. Remember that this is just the required starting torque. The amount of torque required to turn the load can vary with speed. At any point on the speed-torque curve, the amount of torque produced by a motor must always at least equal the torque required by its load. If the motor cannot produce sufficient torque, it will either fail to start the load, stall, or run in an overloaded condition. This will probably cause protective devices to trip and remove the motor from the power source.

Centrifugal Pump

In the following example (Picture 4), a centrifugal pump requires a full-load torque of 600 lb-ft. This pump only needs approximately 20% of full-load torque to start. The required torque dips slightly as the load begins to accelerate and then increases to full-load torque as the pump comes up to speed. This is an example of a variable torque load.

Picture 4: Speed-torque curve for centrifugal pump

The motor selected in this example is a NEMA B motor that is matched to the load. In other words, motor has sufficient torque to accelerate the load to rated speed.

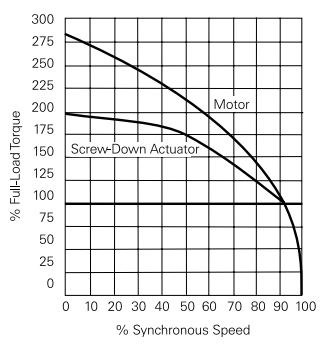

Screw Down Actuator

In the following example (Picture 5), the load is a screw down actuator with a starting torque equal to 200% of full-load torque. Note that the NEMA B motor chosen for this example does not provide sufficient torque to start the load.

Picture 5: Speed-torque curve for screw down actuator

One solution to this problem is to use a higher horsepower NEMA B motor. A less expensive solution might be to use a NEMA D motor which has higher starting torque for the same horsepower rating (Picture 6).

Picture 6: Speed-torque curve of motor sufficient for screw down actuator

No comments:

Post a Comment