Pages

▼

Gasket Sizing for Standard Groove Depths

Nitrile is the chosen example because it is the most commonly used material for transformer gasketing. As shown in table in Gaskets, nitrile compression should be 25 to 50%. Nitrile sheets are available in 1/16-inch-thick increments. Gasket thickness is determined by groove depth and standard gasket thickness. Choose the sheet thickness so that ¼ to ⅓ thickness of the gasket will protrude above the groove. This is the amount available to be compressed (see Picture 1). Gasket sheets come in standard thicknesses in 1/16-inch increments. Choose one that allows a of the gasket to stick out above the groove, if possible, but never choose a thickness that allows less than ¼ or as much as ½ of the gasket to protrude above the groove. Do not try to remove old primer from the groove.

Picture 1: Table - Vertical Groove Compression for Circular Nitrile Gasket

Horizontal groove fill is determined by how wide the groove is. The groove width is equal to the outer diameter (OD) minus the inner diameter (ID) divided by two:

(OD - ID)/2

Or just measure the groove width with an accurate caliper.

Room left for the gasket to expand while being compressed is equal to the width of the groove minus the width of the gasket. For nitrile, the amount of horizontal room needed is about 15 to 25%. Therefore, you need to cut the gasket cross section so that it fills about 75 to 85% of the width of the groove.

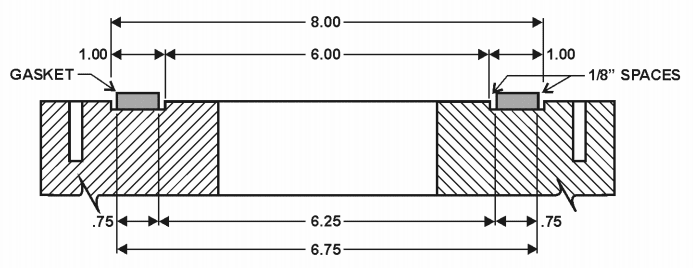

For example, an 8-inch OD groove with a 6-inch ID, (OD-ID)/2 = 1 inch. Therefore, the width of the groove is 1 inch. Because we have to leave 25% expansion space, the width of the gasket is 75% of 1 inch, or ¾ inch. So that the gasket can expand equally toward the center and toward the outside, you should leave one-half the expansion space at the inner diameter of the groove and one-half at the outer. In this example, there should be a total space of 25% of 1 inch or (¼ inch) for expansion after the gasket is inserted, so you should leave ⅛-inch space at the OD and ⅛-inch space at the ID. See Picture 2.

Picture 2: Cross Section of Circular Gasket in Groove

Always cut the outer diameter first. In this example, the outer diameter would be 8 inches minus ¼ inch, or 7¾ inches. To check yourself, subtract the inner radius from the outer radius to make sure you get the same gasket width calculated above. In this example, 3⅞ inches (outer radius, ½ of 7¾), minus 3⅛ inches (inner radius, ½ of 6¼), is ¾ inch, which is the correct gasket width.

NOTE: Since ⅛-inch space is required all around the gasket, ¼ inch must be subtracted to allow ⅛-inch on both sides. The inner diameter would be 6 inches plus ¼ inch, or 6¼ inches. Note that ¼ inch is subtracted from the OD but added to the ID.

No comments:

Post a Comment