The Instrumentation, Systems, and Automation Society (ISA) is one of the leading process control trade and standards organizations. The ISA has developed a set of symbols for use in engineering drawings and designs of control loops (ISA S5.1 instrumentation symbol specification). You should be familiar with ISA symbology so that you can demonstrate possible process control loop solutions on paper to your customer. Picture 1 shows a control loop using ISA symbology. Drawings of this kind are known as piping and instrumentation drawings (P&ID).

Picture 1: Control loop using ISA Symbology: Piping and Instrumentation Drawing

Symbols

In a P&ID, a circle represents individual measurement instruments, such as transmitters, sensors, and detectors (Picture 2).

Picture 2: Discrete Instruments (ISA Symbols)

A single horizontal line running across the center of the shape indicates that the instrument or function is located in a primary location (e.g., a control room). A double line indicates that the function is in an auxiliary location (e.g., an instrument rack). The absence of a line indicates that the function is field mounted, and a dotted line indicates that the function or instrument is inaccessible (e.g., located behind a panel board).

A square with a circle inside represents instruments that both display measurement readings and perform some control function (Picture 3). Many modern transmitters are equipped with microprocessors that perform control calculations and send control output signals to final control elements.

Picture 3: Shared Control/Display Elements (ISA Symbols)

Controllers

A hexagon represents computer functions, such as those carried out by a controller (Picture 4).

Picture 4: Computer Functions (Controllers)

PLCs

A square with a diamond inside represents PLCs (Picture 5).

Picture 5: PLCs

Valves

Two triangles with their apexes contacting each other (a “bow tie” shape) represent a valve in the piping. An actuator is always drawn above the valve (Picture 6).

Picture 6: Valves

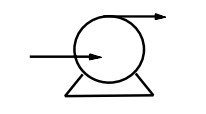

Pumps

Directional arrows showing the flow direction represent a pump (Picture 7).

Picture 7: Pumps

Piping and Connections

Piping and connections are represented with several different symbols (Picture 8):

❑ A heavy solid line represents piping;

❑ A thin solid line represents process connections to instruments (e.g., impulse piping);

❑ A dashed line represents electrical signals (e.g., 4–20 mA connections);

❑ A slashed line represents pneumatic signal tubes;

❑ A line with circles on it represents data links.

Other connection symbols include capillary tubing for filled systems (e.g., remote diaphragm seals), hydraulic signal lines, and guided electromagnetic or sonic signals.

Picture 8: Piping and Connection Symbols

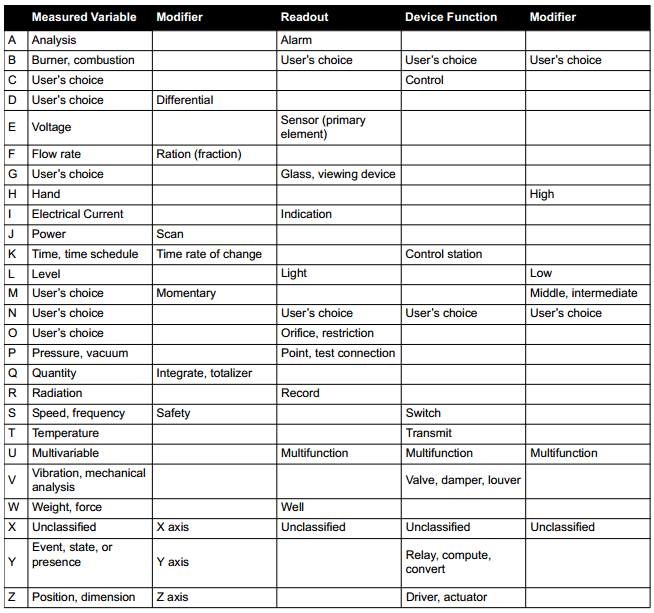

Identification Letters

Identification letters on the ISA symbols (e.g., TT for temperature transmitter) indicate:

❑ The variable being measured (e.g., flow, pressure, temperature);

❑ The device’s function (e.g., transmitter, switch, valve, sensor, indicator);

❑ Some modifiers (e.g., high, low, multifunction).

The table on Picture 9, shows the ISA identification letter designations.

The initial letter indicates the measured variable. The second letter indicates a modifier, readout, or device function. The third letter usually indicates either a device function or a modifier. For example, “FIC” on an instrument tag represents a flow indicating controller. “PT” represents a pressure transmitter. You can find identification letter symbology information on the ISA Web site at http://www.isa.org.

Picture 9: ISA Identification Letters

Tag Numbers

Numbers on P&ID symbols represent instrument tag numbers. Often these numbers are associated with a particular control loop (e.g., flow transmitter 123). See Picture 10.

Picture 10: Identification Letters and Tag Number

No comments:

Post a Comment